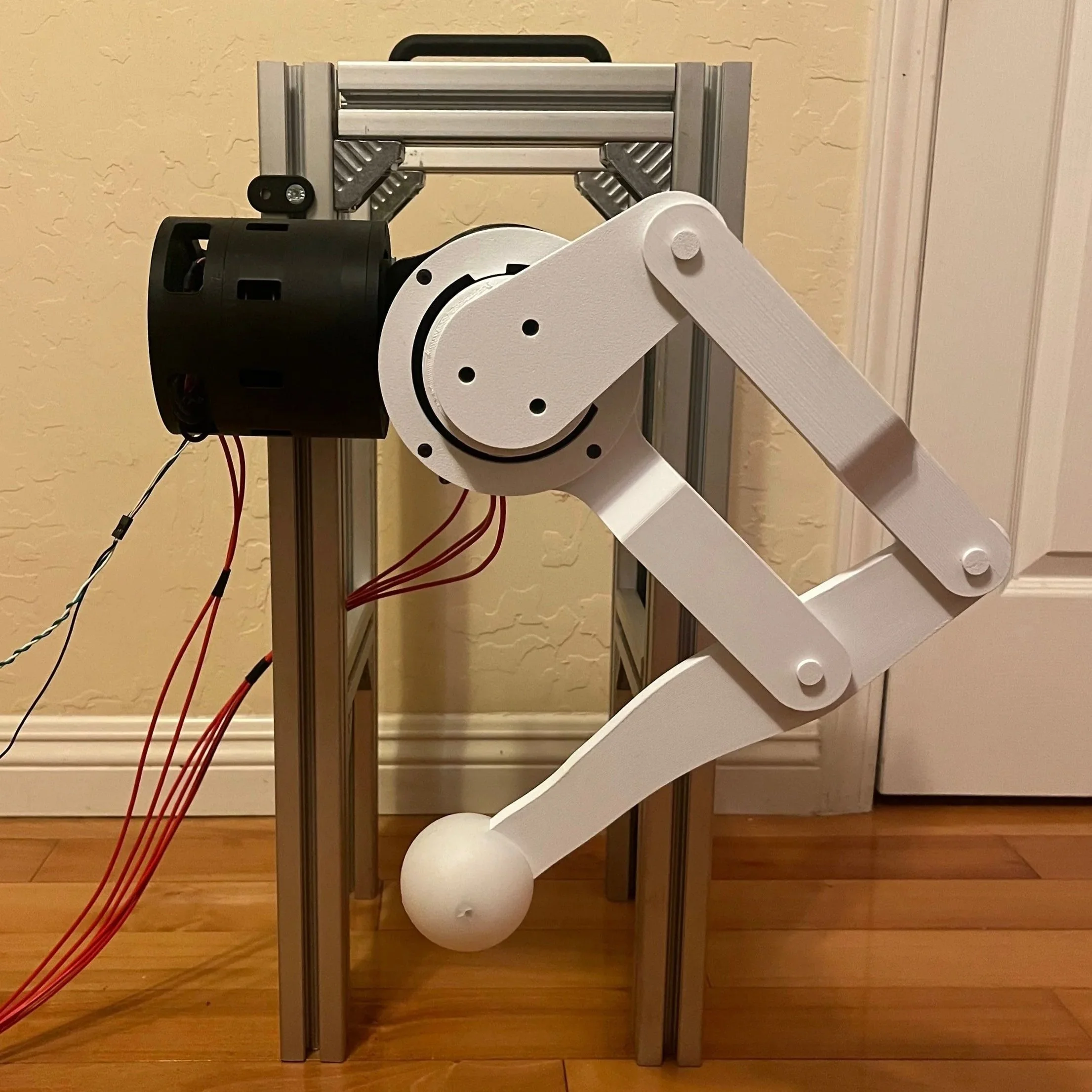

Robotic Quadruped Leg [2025]

Summary and Key Details

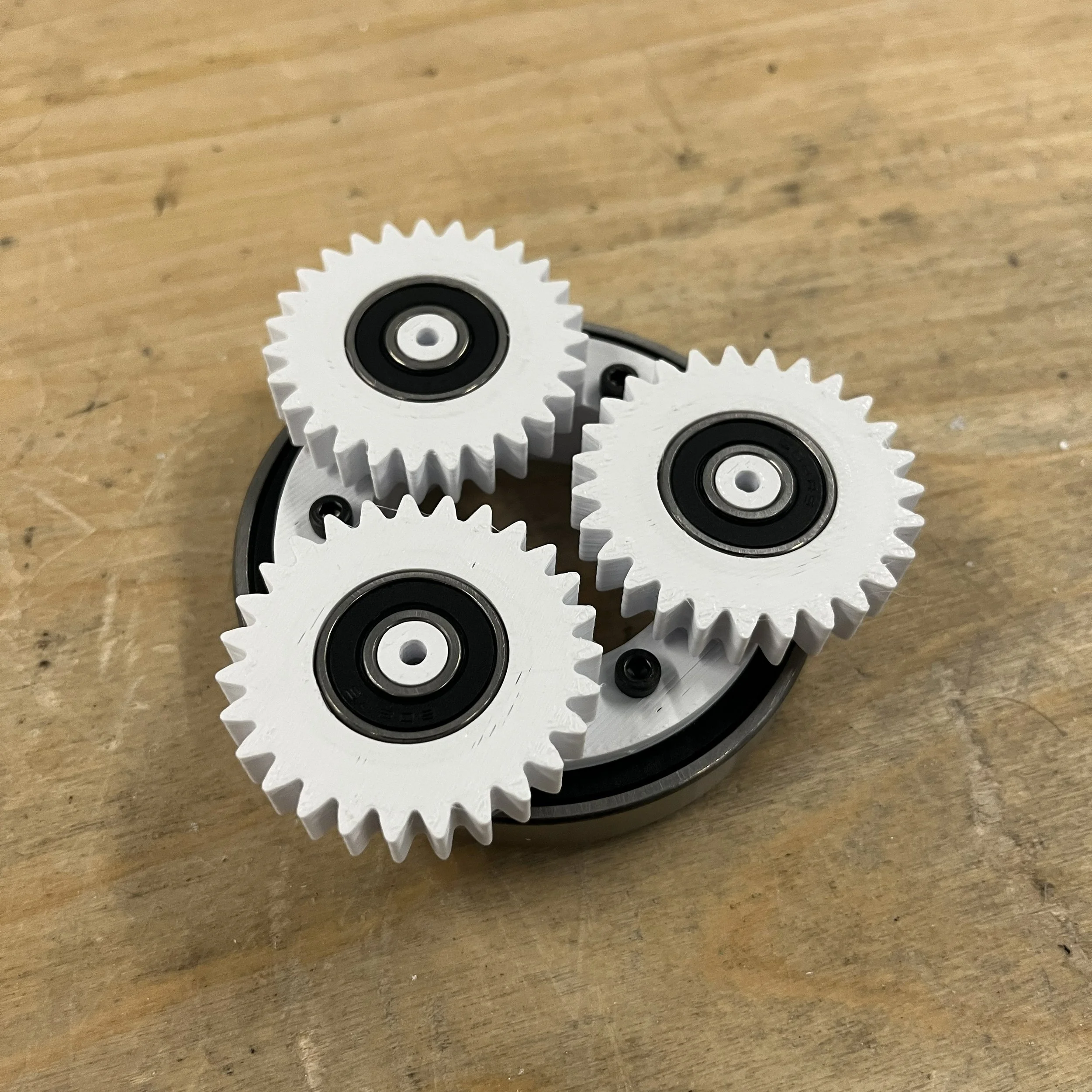

Developed a 3 DoF leg including custom 8:1 planetary gearboxes and a 4-bar linkage to replicate quadruped gait

Implemented inverse kinematics and trajectory planning over CAN bus, enabling closed-loop BLDC control

Designed actuator subassemblies to simplify manufacturing and utilized hard stops for current-based homing

Used improved actuators from of my Planetary Project

Specifications

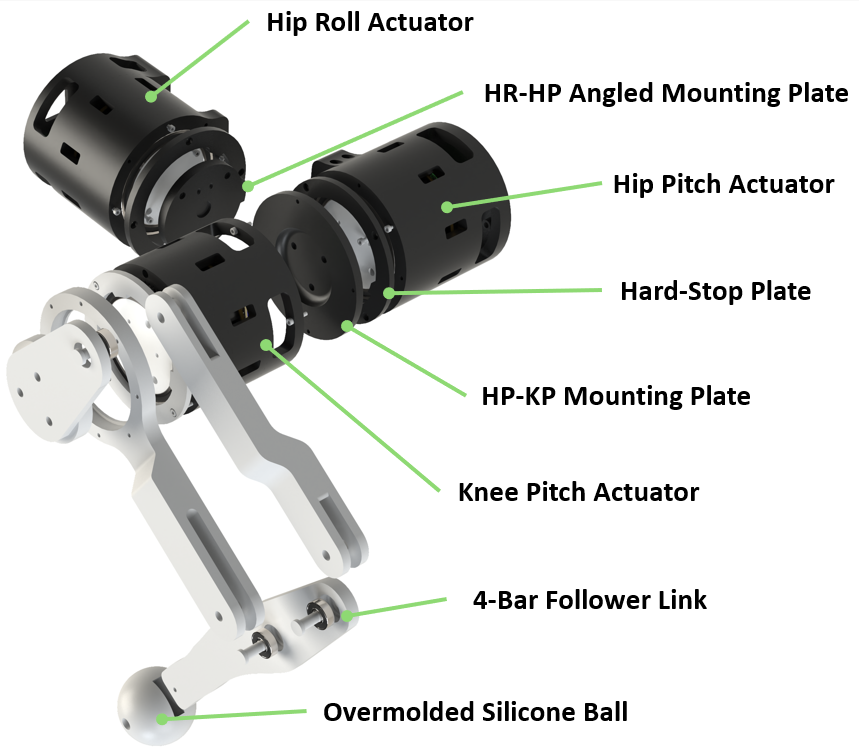

3x Custom Actuators

8:1 Planetary Gearboxes

90 KV BLDC Motor, ODrive S1 Controller

Magnetic Encoder for Closed-Loop Control

4-Bar Linkage for Knee Flexion/Extension

Teensy 4.1 for High-Level Logic

30A Over Molded Silicone Feet for Traction

6S 5200mah LiPo Battery

Continuous Current Output Force (Neutral): 101 N

Total Mass: 3.9 kg

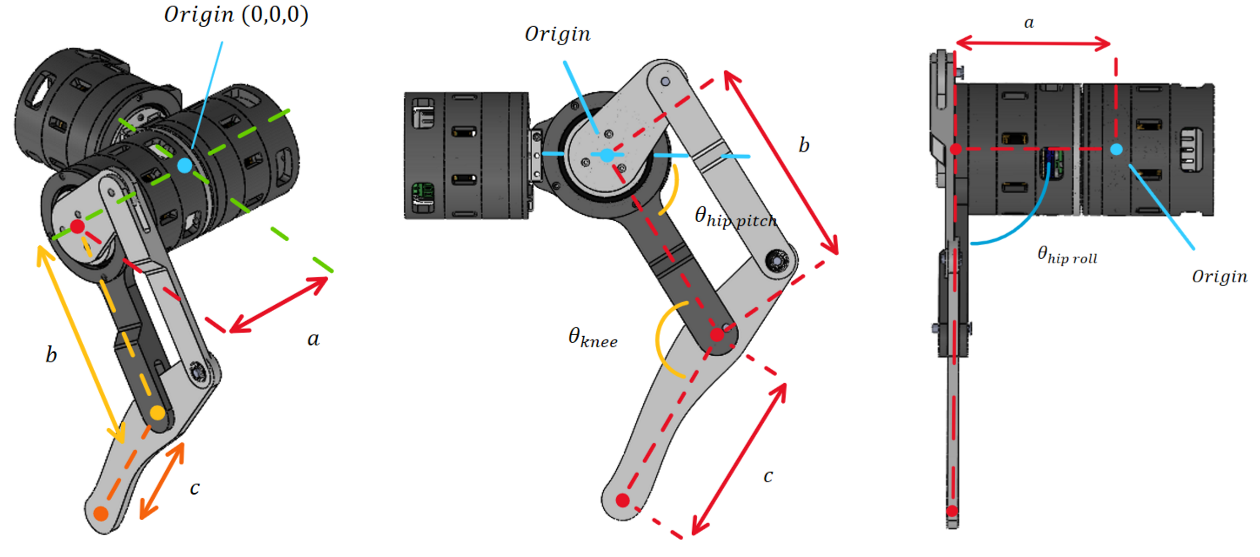

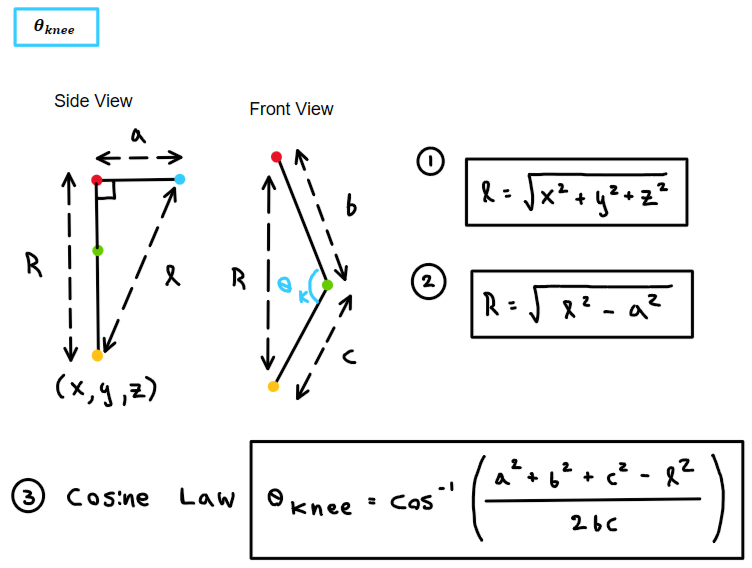

Leg Kinematics and Motion Planning

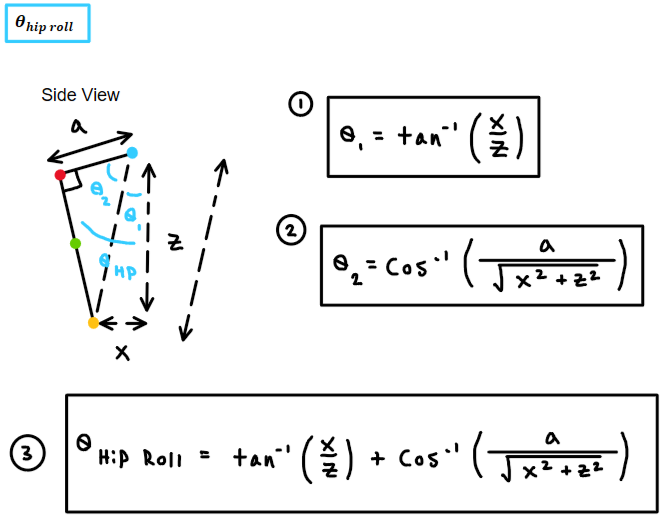

The leg’s inverse kinematics were derived to calculate joint angles for a desired XYZ position, with forward kinematics used to determine the foot position from current joint angles.

I implemented a trajectory planner that interpolates linear, sinusoidal, and circular paths, discretizes them into waypoints, and applies the IK equations at each step, producing predictable motion.

Inverse Kinematic Derivations

Movements

Forward Stepping (Sinusoidal)

Side Stepping (Sinusoidal)

Circular Motions

Sideways Circular Motion

Linear Motions

Fast Steps

Box Steps

Homing Procedure (Hard Stops)

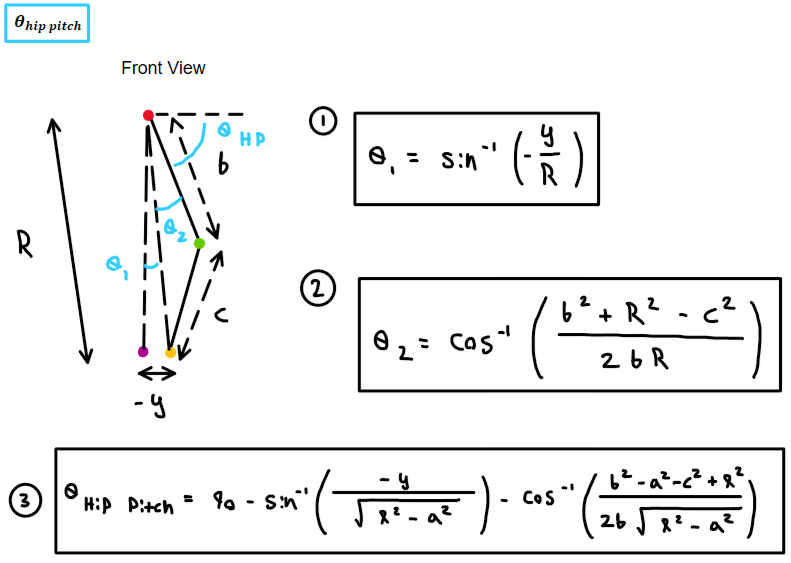

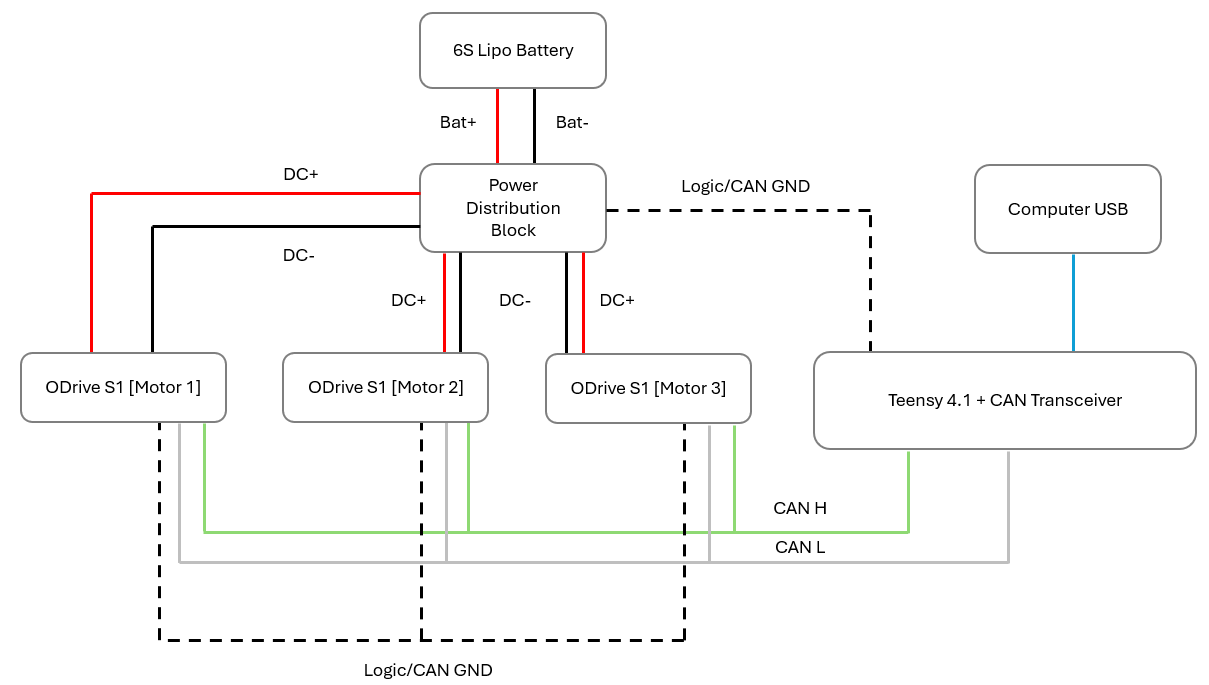

Electrical Architecture

Each actuator has an ODrive S1 mounted behind the motor, leveraging the onboard magnetic encoder for closed-loop position and velocity control.

A Teensy 4.1 serves as the central controller, transmitting and receiving CAN messages via an external CAN transceiver. The ODrives are connected over a daisy-chained CAN bus, reducing wiring complexity.

Power is supplied by a 6S LiPo battery through a power distribution block, with CAN ground tied to DC- to establish a common reference and prevent ground loops.

USB Wiring Diagram

External Power Wiring Diagram

End-Effector Silicone Overmold

To increase friction at the ball end of the leg, I designed and 3D-printed a two-part mold and overmolded a 5 mm thick, 30A Shore hardness silicone layer. This layer increases the coefficient of friction, improving traction while also introducing passive compliance at the ground interface.

For future iterations, the underlying ball geometry should include mechanical retention features such as grooves or undercuts, since the silicone does not strongly adhere to the printed substrate. In the current design, the silicone is mechanically retained once the leg linkage is inserted, locking the overmold in place during operation.

Additional Photos and Videos

Continuous Current Lifting Force

Prototyping Aftermath

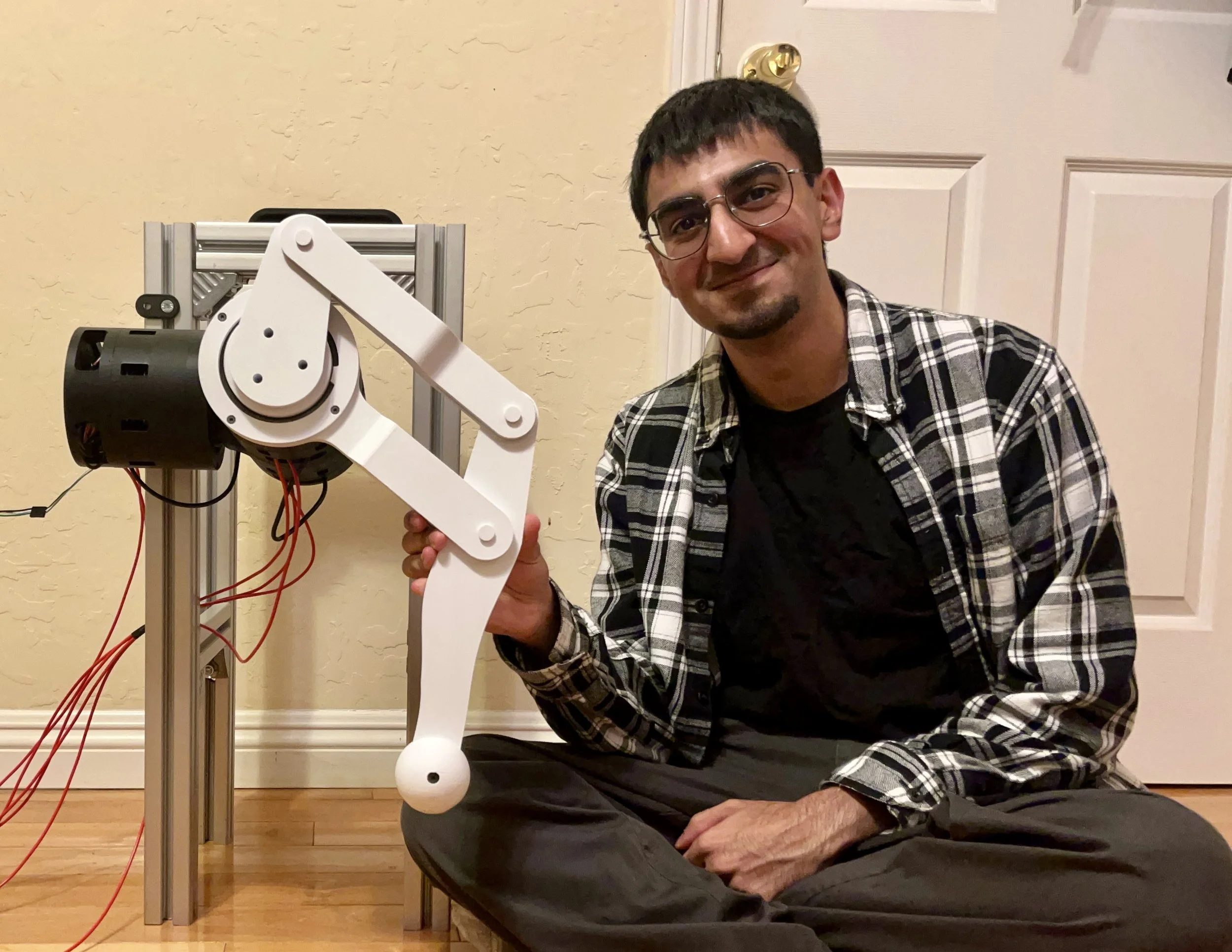

Photo for Scale

Planetary Carrier

Gearbox Output Assembly

Me, relieved that it finally worked

Next Steps

The next phase will focus on mechanical improvements. The actuator interfaces could use greater stiffness, and the linkage would benefit from a redesign to reduce wear with needle and thrust bearings for the pin joints.

The improved leg will then be integrated into a linear rail for dynamic testing. Testing has currently been limited to static force validation, confirming the leg can theoretically support the full quadruped mass.