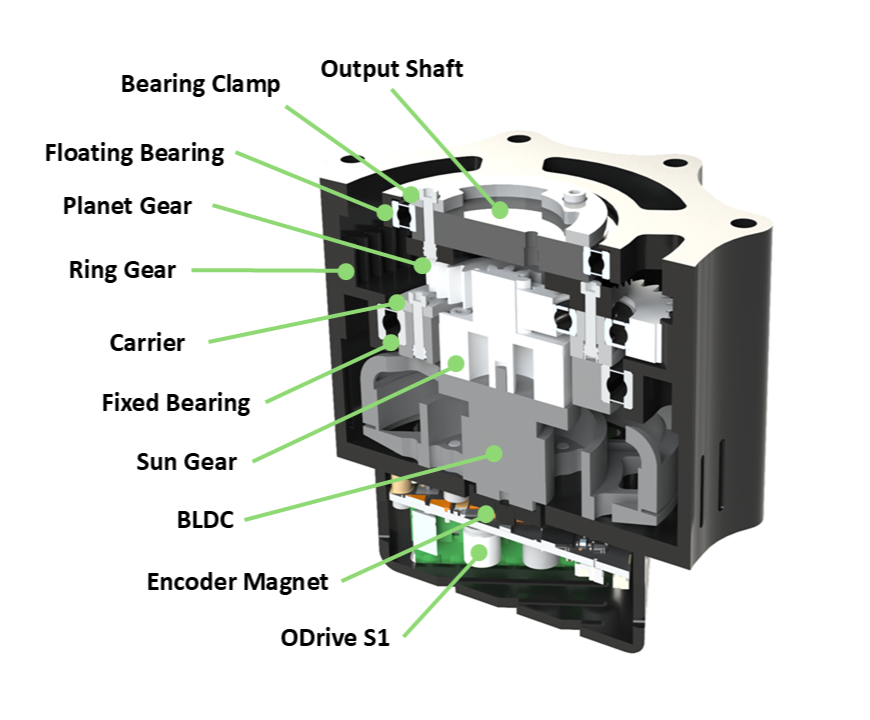

Planetary Gearbox [2025]

Summary and Key Details

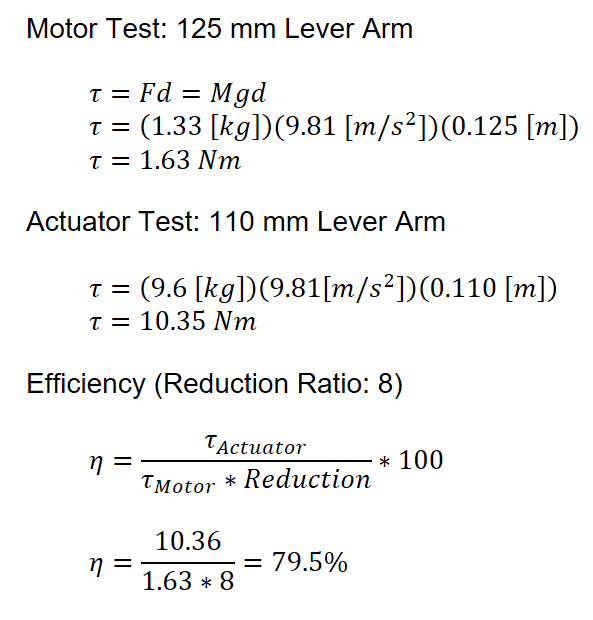

Designed an 8:1 planetary gearbox delivering 12.75 Nm continuous torque at 79.5% efficiency

Implemented a floating shaft support to compensate for axial tolerance stacks affecting bearing performance

Developed a parameterized involute spur gear generator on SOLIDWORKS for the ring, sun, and planetary gears

Specifications

8:1 Planetary Gearbox with Spur Gears

ODrive S1 FOC with Onboard Encoder

Floating Bearing Shaft Support Structure

Continuous Torque: 12.75 Nm

Backdriving Torque: 0.3 Nm

Efficiency: 79.5%

Total Mass: 1.03 kg

Lubrication - White Lithium Grease

Photos and Videos

Close-up Video

High-Speed (Real-time Video)

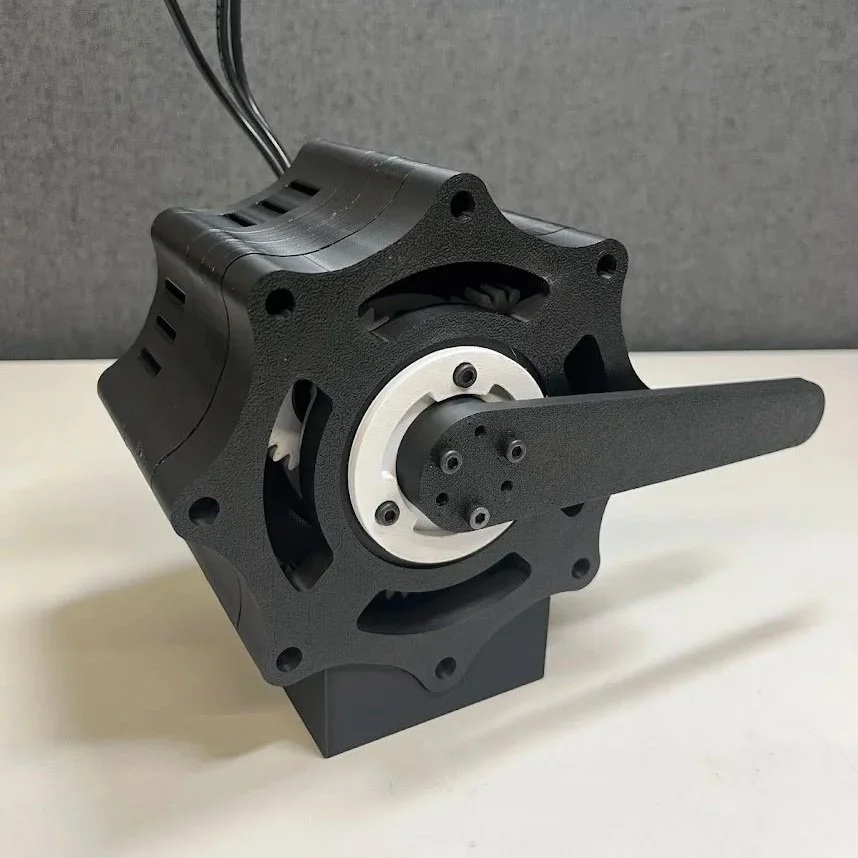

Isometric View

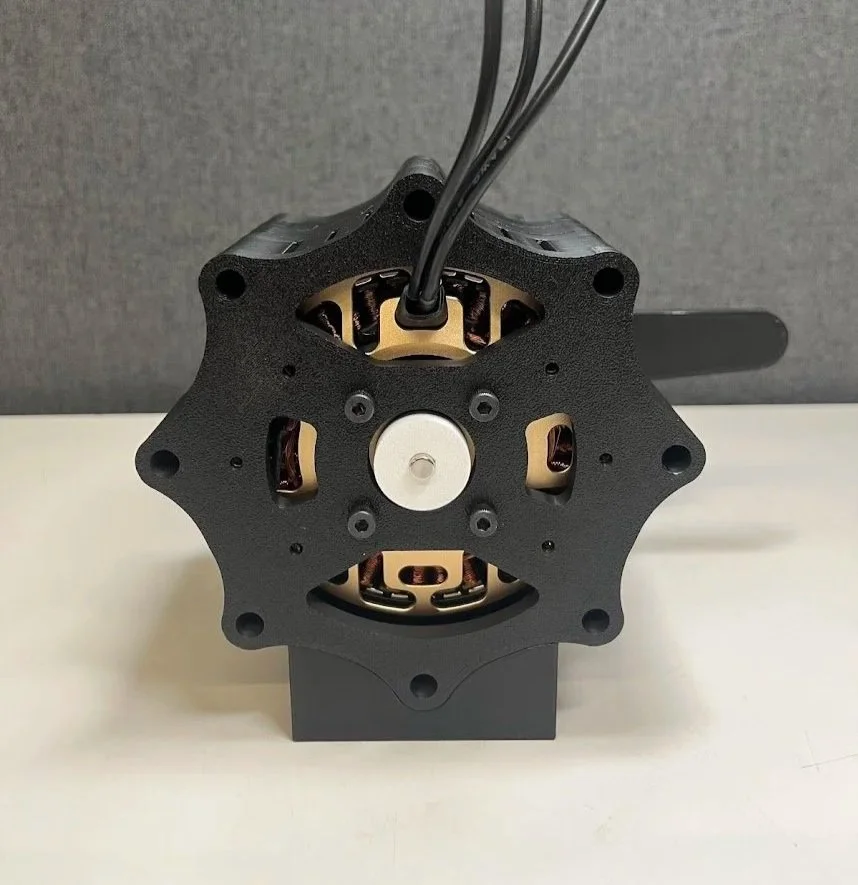

Back View (Encoder)

Actuator Scale

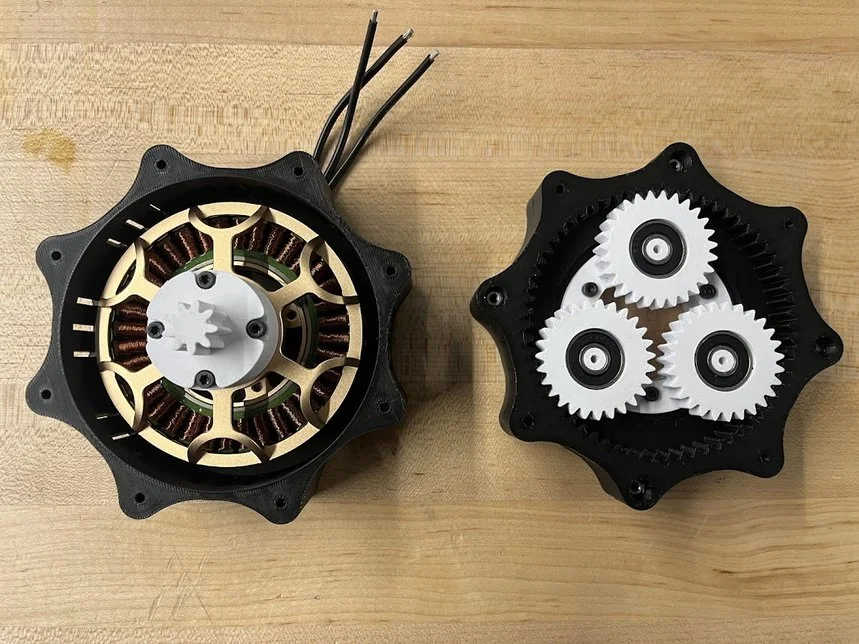

Motor and Gearbox

3D Prints and Bearings

Actuator Mass

Efficiency and Torque Testing

Actuator efficiency was measured by comparing motor torque to gearbox torque. The videos shown are the test setups used. The recorded values differ from those used in the efficiency calculations, as the motor kV was tested and tuned after these videos were taken, and the tests were performed again.

Motor Torque (~70% Continuous Current)

Actuator Torque (80% Continuous Current)

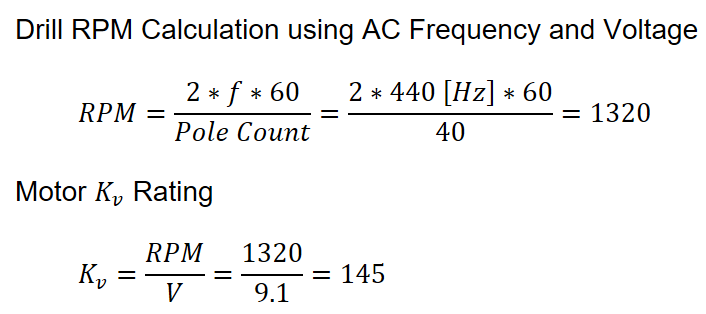

Motor Testing - kV

I chose the Eaglepower 8308 Kv90 motor because its outrunner style rotor and low Kv rating gave it a high torque-per-amp specification.

However, testing with a drill and multimeter showed the actual Kv was higher than expected, resulting in lower torque at the rated continuous current.

For the next design, I may need a higher reduction ratio to meet the project’s torque requirements.

3D Printing

This gearbox went through several design and 3D-printing iterations to get the bearing and gear fits right. The comparison video below shows why this tuning mattered - getting the right gear backlash reduced play without causing the gears to bind.

1st Print - Binding Gears

Improved Backlash