Mimicking Robotic Arm [2023]

Summary and Key Details

This was my first project using CAD and 3D printing - something I look back on to see the progress I've made since then

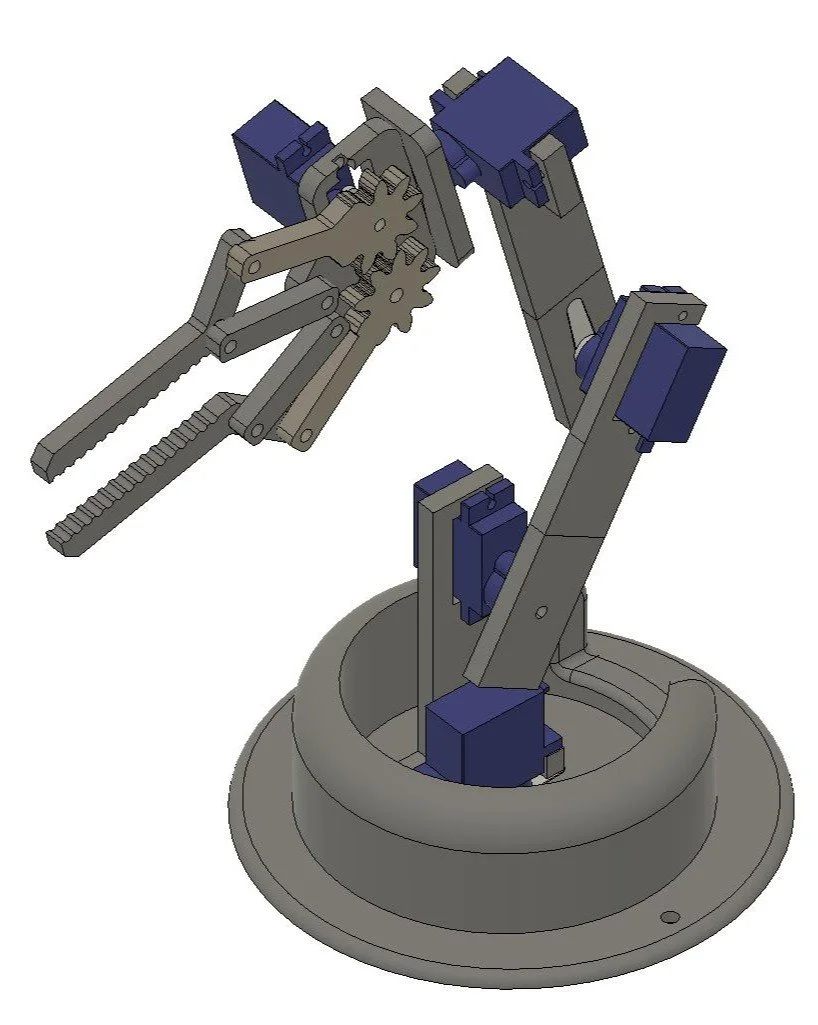

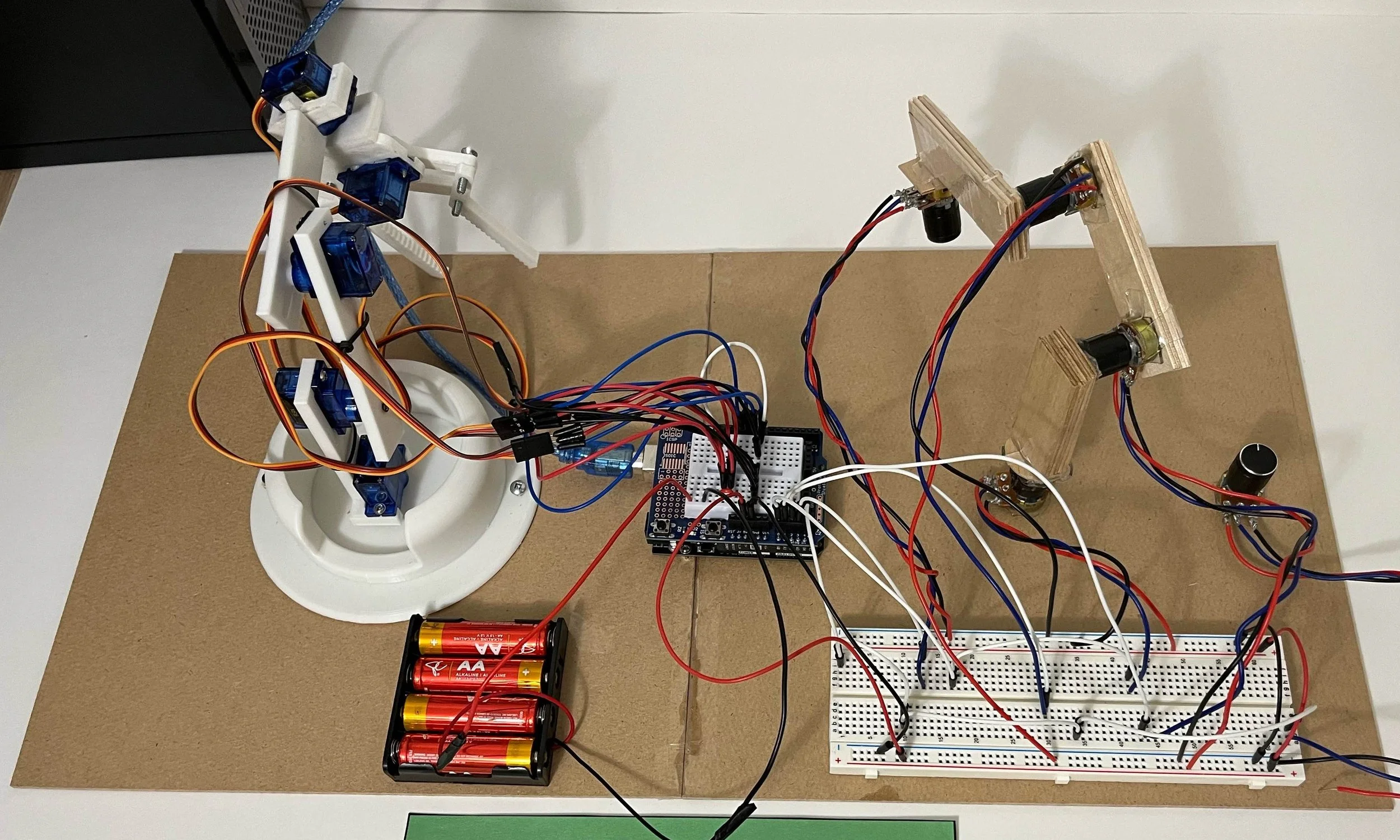

Designed a robotic arm that replicates the real-time movements of a manually controlled arm

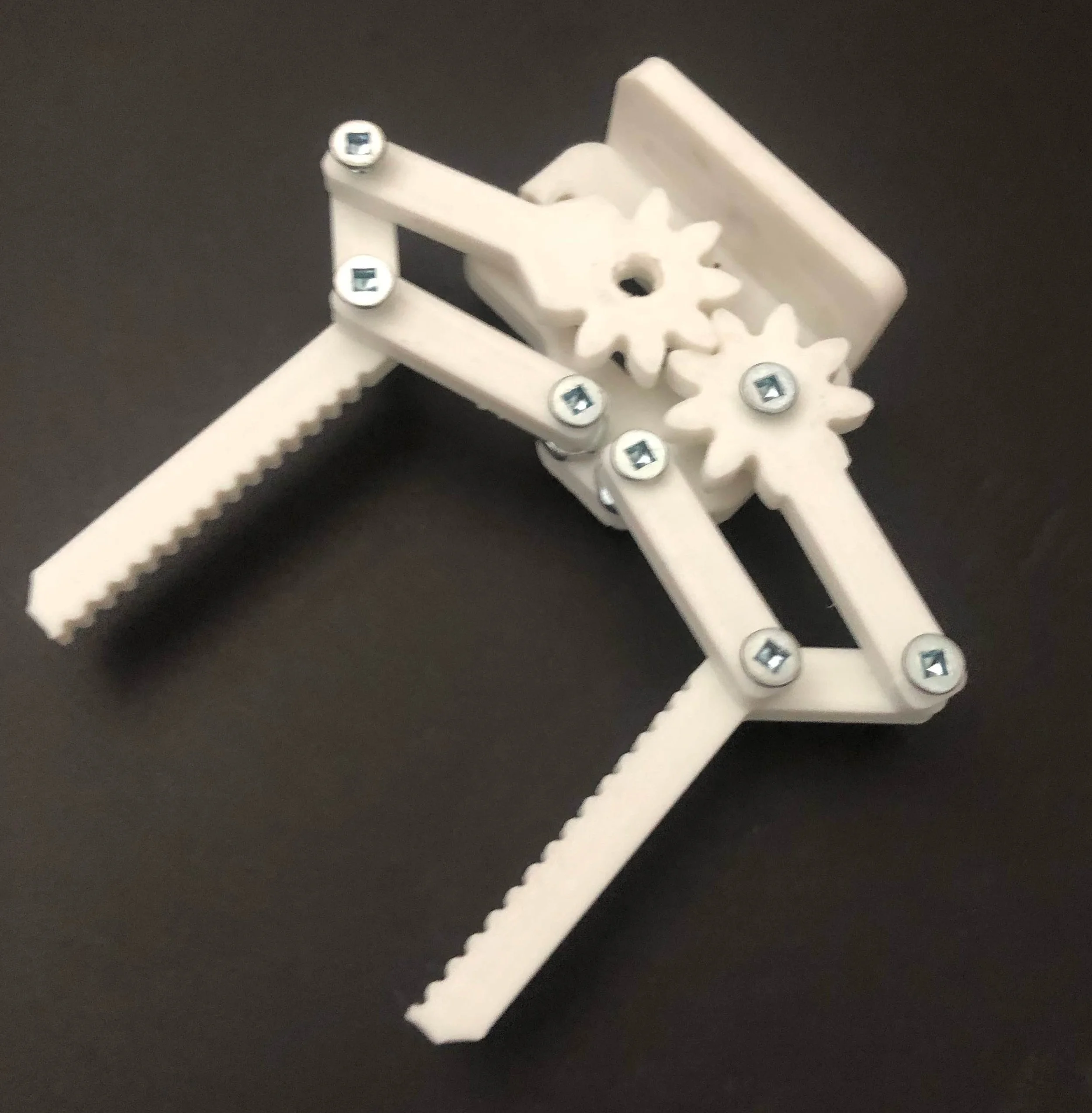

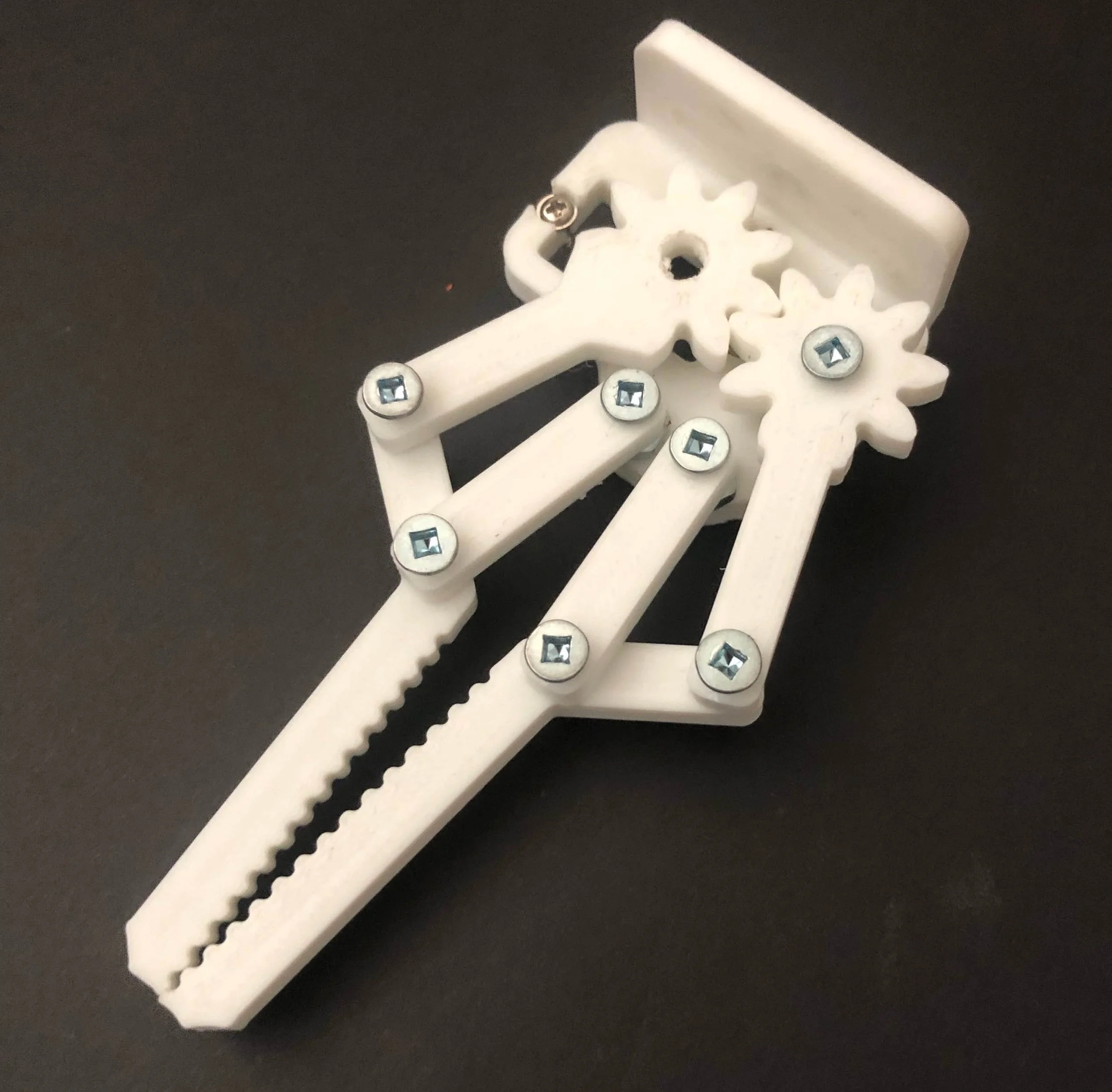

Obtained a 2:1 strength-to-weight ratio, and modelled a 4-bar linkage claw to manipulate objects

Robotic Arm Design

Though programmed movements of robots can provide precise control, I wanted to explore how intuitive human input could bridge the gap in controlling complex systems.

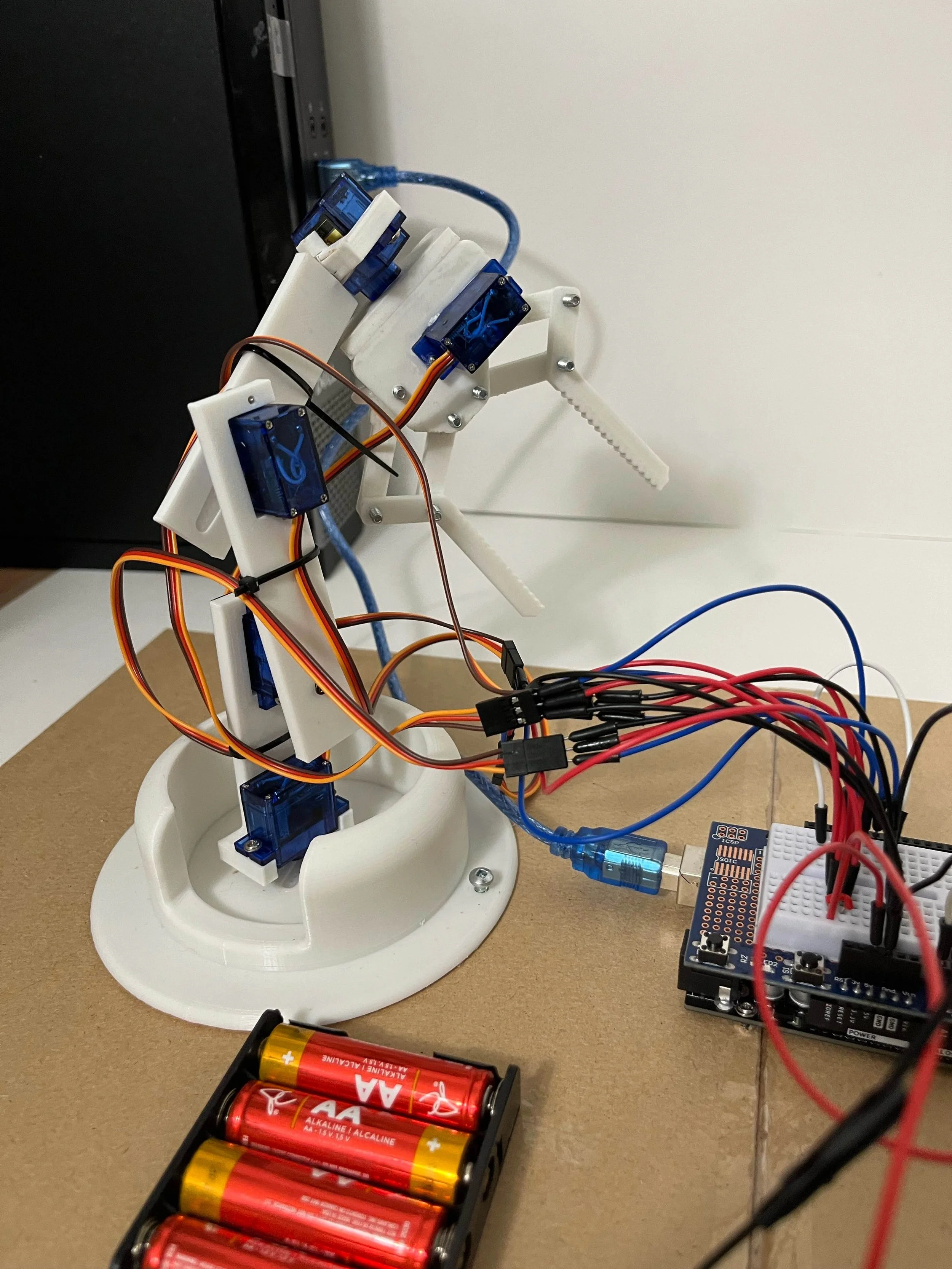

For the main robotic arm, I utilized SG90 servo motors to control movements and to drive the 4-bar linkage end effector. The body of the robotic arm consisted of 3D printed PLA components.

Control Arm Design

The control arm followed a very “frugal” design, built entirely from scrap wooden pieces cut to match the linkage lengths of the main robotic arm. Each joint was connected using a potentiometer.

These potentiometers allowed the main arm to mimic the control arm’s movements. Once wired to the Arduino and paired with the servo motors, I coded the motors to match the changes seen in the potentiometer position.

Reflection and Improvements

The system achieved its purpose but fell short of the performance I envisioned—the SG90 motors struggled with the arm’s weight, limiting speed and responsiveness.

If I were to revisit this project, I would make a lot changes, namely using stronger motors and improving their shaft support structures. I could also incorporate the gearboxes I've made in my other projects!

Though this project may not be perfect, looking back, it shows how much I have grown from the start of my engineering journey, to now. Nothing is more important than improvement.